Beginner’s Guide to 3D Printing

Diving into the world of 3D printing can feel like stepping into a sci-fi workshop, but it’s far more approachable than it seems. This guide is designed for beginners, breaking down the essentials of 3D printing—from setting up your printer to troubleshooting your first creations—without overwhelming you with technical jargon. Using standard 3D printer filament, we’ll walk you through the process of turning digital designs into tangible objects, empowering you to create with confidence.

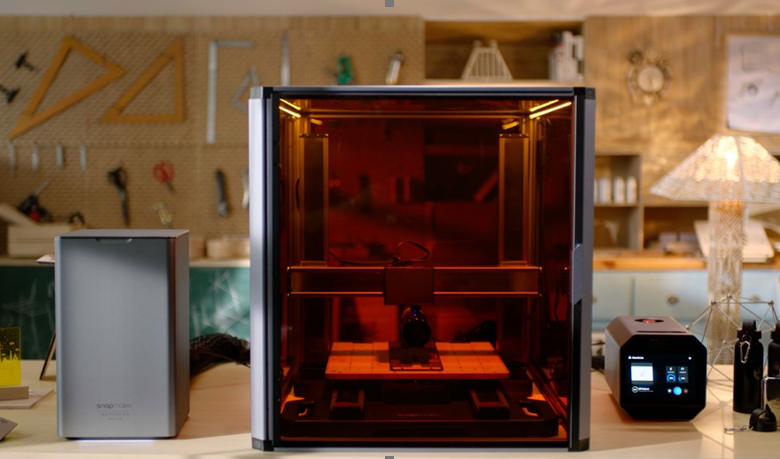

Understanding Your 3D Printer

Most beginner-friendly 3D printers use Fused Deposition Modeling (FDM), a process where melted filament is layered to form objects. To get started, familiarize yourself with these core components:

- Motion System: This includes rails and belts that move the print head along the X, Y, and Z axes, ensuring precise placement of filament.

- Hot End: The nozzle that heats filament (typically to 200–300°C) and extrudes it layer by layer.

- Build Plate: The surface where your print takes shape. Many are heated to improve adhesion and prevent warping.

Understanding these parts helps you troubleshoot issues and maintain your printer effectively.

Beyond the printer, a few tools will make your experience smoother:

- Isopropyl Alcohol (90%+): Cleans the build plate for better print adhesion.

- Digital Calipers: Measures dimensions to ensure accuracy during calibration.

- Spatula or Scraper: Safely removes finished prints from the build plate.

- Tweezers: Handy for clearing small bits of filament or supports.

These tools are inexpensive and widely available, setting you up for success from the start.

See also: How to Spot a Good CPR AED Certification in Jacksonville, FL

Mastering the Software Workflow

3D printing involves a digital-to-physical process, and software plays a critical role. Here’s a step-by-step breakdown:

Step 1: 3D Modeling

Start with beginner-friendly design software like Tinkercad, a free, browser-based tool that lets you create simple shapes and prototypes. For more advanced users, Blender or Fusion 360 offers greater control, though they have steeper learning curves.

Step 2: Slicing

Once your model is ready, a slicer program like Ultimaker Cura (free and widely used) converts your 3D model into instructions your printer understands, known as G-code. The slicer determines how the printer will build your object layer by layer.

Step 3: File Transfer

Transfer the G-code to your printer via a USB drive, SD card, or direct computer connection, depending on your printer’s capabilities.

Key Slicer Settings to Know

- Layer Height: Affects print speed and quality. For most projects, 0.2mm is a good balance of detail and speed.

- Infill Density: Determines how solid your print is inside. A 20% infill is sufficient for most non-functional parts.

- Supports: Enable these for overhangs steeper than 45 degrees to prevent collapse during printing.

| Layer Height | Printy Time | Surface Quality |

| 0.3mm | 1h 10m | Visible layers |

| 0.2mm | 1h 45m | Smooth |

| 0.1mm | 3h 30m | Mirror-like |

Your First Print: Step-by-Step

Loading Filament

Start with PLA filament, a beginner-friendly material that’s affordable and easy to work with. Here’s how to load it:

- Heat the nozzle to the filament’s recommended temperature (around 200°C for PLA).

- Insert the filament into the extruder until you feel resistance.

- Watch for steady extrusion from the nozzle, ensuring no bubbles or discoloration.

Leveling the Build Plate

A level build plate is critical for successful prints. Try these methods:

- Manual Leveling (Paper Test): Adjust the bed until a piece of paper slides between the nozzle and bed with slight resistance.

- Auto-Leveling: If your printer has this feature, follow its calibration routine for precise results.

Monitoring the Print

Pay close attention to the first three layers, as they set the foundation for your print. Look for:

- Even adhesion with no lifting at the edges.

- Consistent filament flow with no gaps or excess material.

If issues arise, pause the print and address them to avoid wasting time and filament.

Troubleshooting Common Problems

Even seasoned printers encounter hiccups. Here are solutions to common beginner issues:

- Poor First Layer Adhesion: Relevel the bed, increase the build plate temperature by 5°C, or apply a thin layer of glue stick for better grip.

- Stringing (Wispy Strands Between Parts): Enable retraction in your slicer settings or lower the nozzle temperature by 5–10°C.

- Layer Shifting: Tighten the belts on the motion system or reduce print speed by 20% to stabilize movement.

Keep a notebook to track what works for your specific printer and filament, as small tweaks can make a big difference.

Tips for Success and Growth

Start Simple: Begin with small, easy projects like keychains or phone stands to build confidence. PLA filament is ideal for beginners due to its low printing temperature and minimal warping.

Experiment Gradually: Once you’re comfortable, try more complex designs or experiment with filaments like PETG or ABS for different properties.

Join Communities: Platforms like Reddit’s r/3Dprinting or the X Platform offer tips, inspiration, and troubleshooting advice from experienced users.

Conclusion

3D printing is an exciting blend of creativity and technology, and its fundamentals are within reach for anyone willing to learn. By starting with PLA filament and simple projects, you’ll build the skills to tackle more ambitious designs over time. Mistakes are part of the process—each failed print teaches you something new. As you experiment, troubleshoot, and refine your approach, you’ll unlock the potential to create everything from practical tools to intricate art. Grab your printer, dive in, and start bringing your ideas to life!